In process of highly clear and accurate line alignment out of hand reaching, unless the use of quite professional line measuring device, it is not able to avoid mistake caused by manual operation. In real industrial and high tech line aligning work fields, according to the selection of glass lens red line laser module and quite easy connect with an external electric power source, it will easily generate a highly clear and fine line indication on any targeting surface. Anytime this compact structure made laser line generator gets proper installation and adjustment, it is getting reduced relying on professional skills to achieve highly clear and rapid line alignment on desired working surfaces effectively.

For instance, when line alignment is processed for textile garment processing work, it is required to make extremely fine and accurate line projection during the whole process of garment making, cutting and line positioning works etc. In order to avoid mistake caused by manual operation, this red line laser module gets excellent use of high quality glass coated lens or separate crystal lens. Not the same as formal plastic coated lens, even though red line alignment is processed continuously or in long distance, this laser line generator is projecting high linear quality red reference line in distance.

In occasion that red line laser module is employing glass coated lens within selectable lens degree within 10 degree to 110 degree, it is projecting different line length within 0.5 meter to 6 meters. In front part of laser beam aperture, it is specially designed with glass window. When line alignment is processed under quite harsh working environments, it is keeping highly stable line projection, including those of moisture and dust working occasion etc. In formal line alignment work, this laser line generator should be operated within 8 to 10 hours per day. Only if there is enough time reserving as laser module cooling down, it is just making sure of quite nice laser light cycling use and reduced possibility of laser diode and electric driving circuit burning out in constant work.

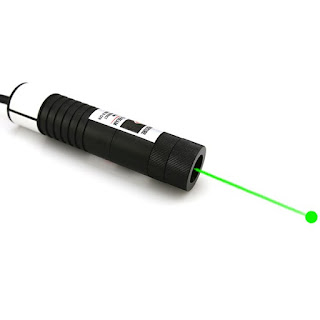

When 650nm red line laser module is being made with quite compact structure aircraft used aluminum alloy housing tube, designed with 16mm or 26mm tube diameter, it is easily installed on any industrial device or equipment, and then achieving highly clear red reference line projection on any vertical or horizontal surfaces effectively. If highly intense and powerful red light and thermal energy are produced from beam aperture, besides its operation for quite long distance line alignment, user should also pay high attention to laser safety issues ad wear 650nm wavelength preventing laser safety goggles until achieving free and accurate line generation constantly.

For instance, when line alignment is processed for textile garment processing work, it is required to make extremely fine and accurate line projection during the whole process of garment making, cutting and line positioning works etc. In order to avoid mistake caused by manual operation, this red line laser module gets excellent use of high quality glass coated lens or separate crystal lens. Not the same as formal plastic coated lens, even though red line alignment is processed continuously or in long distance, this laser line generator is projecting high linear quality red reference line in distance.

In occasion that red line laser module is employing glass coated lens within selectable lens degree within 10 degree to 110 degree, it is projecting different line length within 0.5 meter to 6 meters. In front part of laser beam aperture, it is specially designed with glass window. When line alignment is processed under quite harsh working environments, it is keeping highly stable line projection, including those of moisture and dust working occasion etc. In formal line alignment work, this laser line generator should be operated within 8 to 10 hours per day. Only if there is enough time reserving as laser module cooling down, it is just making sure of quite nice laser light cycling use and reduced possibility of laser diode and electric driving circuit burning out in constant work.

When 650nm red line laser module is being made with quite compact structure aircraft used aluminum alloy housing tube, designed with 16mm or 26mm tube diameter, it is easily installed on any industrial device or equipment, and then achieving highly clear red reference line projection on any vertical or horizontal surfaces effectively. If highly intense and powerful red light and thermal energy are produced from beam aperture, besides its operation for quite long distance line alignment, user should also pay high attention to laser safety issues ad wear 650nm wavelength preventing laser safety goggles until achieving free and accurate line generation constantly.